In this article, we are going to know about the petroleum refining process or crude oil treatment process (Fractional Distillation). Most of the liquid fuels in use today are obtained from crude oil found deep in the earth’s crest. The meaning of petroleum word is => Petro mean rock and Oleum mean oil.

Petroleum Refining Process:

The petroleum is pumped from the ground and it is a mixture of wet gases (methane, propane, ethane) and liquids.

By passing the petroleum through a separator the natural gasoline is absorbed from the wet gas and removed. The result we get is a dry gas and it is known as natural gas.

Since the crude oil obtained from wells is an emulsion of oil and saltwater, this mixture is allowed to flow between two highly charged electrodes. The colloidal water droplets combine to form large drops and they separate out from oil.

The above oil is further treated with copper oxide in order to remove harmful sulfur compounds. It results in the formation of copper sulphide which is then removed by the filtration process.

See also CRDI System

What is Fractional Distillation?

After the removal of useless ingredients and impurities as discussed above, the remainder crude oil is separated into commercially accepted products like gasoline, kerosene, diesel, lubricating oils, etc by the process called fractional distillation.

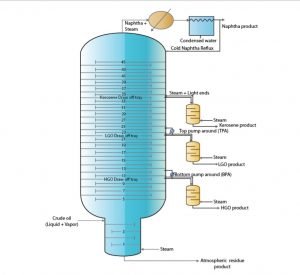

The crude oil then heated up to 600° C in a steel retort where all volatile constituents except the residue are evaporated. The hot vapors then passed into the cylindrical fractionating tower about 30 m high.

The fractionating tower contains the number of horizontal stainless steel trays at short distances. Each of these trays is provided with small chimney which is covered with a loose cap.

When vapors go up in the tower, they become gradually cooler. It results in a condensation of various compounds at different heights if the column due to the cooling of vapors as it goes up.

The compounds with higher boiling temperatures get condensed out at lower levels while those with lower boiling temperatures move up and get condensed turn by turn at the various tray.

Some of the compounds obtained by fractional distillation do not coincide with commercial demand, therefore, these compounds are converted into fractions for which there is more demand.

Some of the petroleum refining process or crude oil refining process used for conversion of fractions into useful compounds are given below:

See also: Working of simple carburetor

Different petroleum refinery processes:

- Cracking (Thermal cracking & catalytic cracking)

- Polymerization

- Hydrogeneration

- Alkylation

- Isomerization

- Reforming

- Cyclization

- Aromatization

In this article, we are learned about the complete petroleum refining process and fractional distillation. If you have any doubts about this article then put it in the comment box.