|

| Diagram of carburetor |

Before we jump to start learning about different types of carburetors in I C Engines, What is mean by carburetor? let’s elaborate it first.

Table of Contents

What is carburetor?

In a simple language, for the combustion or burning in the combustion chamber at all operating conditions, we need a proper mixture of air and fuel. To make this proper air-fuel mixture, we need a mechanical device, and that mechanical device is a carburetor.

The carburetor regulates the air-fuel ratio and thus, controls the speed of the engine. Fuel used in the process of carburetion is always volatile fuel. Petrol, benzol, and alcohol are some volatile fuels used in the carburetion process.

Read about: Working of solex carburetor

Let’s come to the main part of this article,

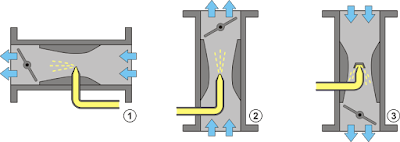

In this article, we are going to classify types of carburetors in automobile engineering based on the direction of air and fuel flow in the carburetor. Depending upon directions of air and fuel, there are three types of carburetors as follows:

Types of carburetors:

- Updraught carburetors

- Downdraught carburetors

- Horizontal or side draught carburetors

|

| Diagram of different types of carburetors |

Let’s declutter these three types of carburetors one by one.

Updraught carburetor:

As a name suggest, in updraught carburetors, air enters the carburetor from the bottom side and goes towards the upward side against gravity. This carburetor has to lift the sprayed fuel droplets by air friction and this a main disadvantage of updraught carburetor.

In this carburetor, a cross-section of the jet tube is small and thus, the carburetor can not supply the air-fuel mixture at rapid speed during the high speed of the engine. This big disadvantage makes this carburetor defunct or obsolete.

Downdraught carburetor:

In downdraught carburetor, the flow of the mixture enters the carburetor from the upside and goes towards the downside with the help of gravity. We can also call it as a gravity-assisted carburetor. Due to this up-down characteristic of a carburetor, it usually installed at a level higher than the intake manifolds. This carburetor allows the proper flow of mixture at high and low engine speed.

Horizontal or side draught carburetor:

This type carburetor used when we have the constraint of space for assembly. In horizontal or side draught carburetor, as a name suggest, the jet tube is placed in a horizontal direction. One more advantage of this type of carburetor is that it reduces the resistance of the flow due to the absence of the right angle mechanism in the intake area.

Read about Working and diagram of carter carburetor

Why carburetors are used in petrol engines, not in diesel engines?

One thing you understand about a carburetor is that, automobile industry use carburetor only in a petrol engine, not in a diesel or compression ignition engine (C I Engine). In a diesel engine, we use hot compressed air coming from turbocharger or respiration(natural) to burn the fuel in the combustion chamber.

Conclusion:

In the above article, we have discussed about carburetors and different types of carburetors in I C Engine. If you have any query or wants to discuss or suggest anything about this article, feel free to use our comment section and discuss it with our other readers.

Our downloads:

Download pdf of types of carburetors from our google drive storage => types of carburetors pdf

Also, you can download ppt of types of carburetors from the same storage => types of carburetors ppt